Forum

Market

- rcbs 45 basic hylser cal til 8x58R danish krag

- Nydelig publisert Webley No. 5 Army Express

- Engelsk pattern 1751 infanteri sabel

- Engelsk spadroon

- Smith & Wesson model 2.

- Kjøper Engelske millitære flintlåsvåpen

- " Hevarm " til Kongsberg kammerlader

On this day

28 October 1834

The Pinjarra Massacre was an attack that occurred at Pinjarra, Western Australia on a group of up to 80 Noongar people by a detachment of 25 soldiers, police and settlers led by Governor James Stirling in 1834. After attacks on the displaced Swan... Read more ...

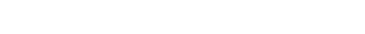

The Pinjarra Massacre

The Pinjarra Massacre was an attack that occurred at Pinjarra, Western Australia on a group of up to 80 Noongar people by a detachment of 25 soldiers, police and settlers led by Governor James Stirling in 1834. After attacks on the displaced Swan River Whadjuk people and depredations on settlers by a group of the Binjareb people led by Calyute had, according to European settlers, reached unacceptable levels, culminating in the payback killing of an ex-soldier, Stirling led his force after the party.

Arriving at their camp, five members of the pursuit party were sent into the camp to arrest the suspects and the Aborigines resisted. In the ensuing melee, Stirling reported 15 killed (eleven names were collected later from Aboriginal sources); police superintendent T.T. Ellis later died of wounds and a soldier was wounded. Stirling warned the tribe against payback killings and arranged a peace between the warring tribes, but Calyute continued to break it by raiding the Whadjuk until his demise.

Chat

Offline

No chatting right now.

(You must be logged in to the forum to chat.)

Featured article

It has long been an established fact that so called multiple discharges or chainfires in percussion revolvers originates from the chamber mouth of the cylinder. But, is this a myth, or are there other explanations? This article seeks to prove that multiple discharges may just as well be caused by loose fitting caps.

Multiple Discharges in Percussion Revolvers

Home-Made Hammer Swaged Bullets

About

AboutPublished: 19 September 2008 by Øyvind Flatnes.

Edited: 19 September 2008.

Views: 40427

Les artikkel på norsk

Les artikkel på norskIt may be discussed whether cast or swaged bullets are best. Of course, both have its advantages, but the disadvantage with swaged bullets is that they are harder to make for the average shooter. However, it is not impossible. Professional equipment is available from companies such as RCE Co. and Corbin, but swaging presses and tools are expensive.

During the latter part of the 1800s many competitive muzzleloading shooters used so called 'hammer swages' which was a die where the bullets were swaged by the force of a hammer. The muzzleloading schuetzen rifles that used such bullets often had a false muzzle to facilitate the loading of the heavy paper patched slugs. A hammer swage is not difficult to make if you have access to a lathe. Swaged bullets normally don't have grease grooves and are best suited for paper patching.

My attempt to make a prototype of a hammer swage was actually quite successful. The swage is made up from three parts: a steel cylinder which is bored exactly to the diameter of the finished bullet, a bolt that forms the bullet base and a bolt that forms the bullet nose. The tool is simple to use. A lead slug with a light coating of RCBS case lube is inserted into the cylinder. The nose forming bolt is inserted in one end of the cylinder and the base forming bolt into the other. The bullet is formed with a couple of hard blows from a hammer against the base forming bolt. That's it, and the finished bullet can be removed from the cylinder.

Find out more!

You can learn more casting and swaging bullets for black powder guns in the brand new book From Musket to Metallic Cartridge: A Practical History of Black Powder Firearms.

I used a .437" cast smooth sided bullet that I paper patch for .45-70 ammunition as a basis for the bullets. After it was run through the hammer swage the diameter had increased to .454". The finished bullets were going to be paper patched and shot in a .577/450 Martini-Henry Mk IV. The bullet nose was changed and the new bullet got a cup base. Bullets may be swaged from lead wire that is cut in appropriate pieces or you can make a mould that cast slugs of proper weight. If you make a device that allows you to adjust the length of the slug, the mould can be used as a basis for swaging bullets in many different calibres.

The nose of my prototype bullet looks ridiculous, but it only meant as a just a test. To say the least, it is not very aerodynamic! I have now modified the nose so that it looks a bit better, and it actually shoots ok in the Martini-Henry. The advantage of a hammer swage like this is the opportunity to make a number of different nose and base forming bolts. The length can also be varied until you have a bullet that is optimal for your rifle. To change the diameter of the bullet you need to make a new cylinder.

The disadvantage of swaged bullets is the production time. First you must make the lead slug from which the bullet is swaged. If you have access to lead wire you will save some time, but at least here in Norway, lead wire is not readily available. On the other hand it is simple to cast a couple of hundred slugs that can be used to swage bullets in a number of different calibres. If you simply want to experiment with a few bullets it takes less time to swage them compared to start melting lead, wait for it to heat, heat the moulds and cast a couple of bullets. I have tested the bullets briefly, and you can see the results in the article about the .577/.450 Martini.Henry rifles.

From left to right: A basis bullet, a finished bullet from the hammer swage and a paper patched bullet from the hammer swage. Picture 2: Bullet nose and cup base. Picture 3: Two swaged lead bullets. Finally, a cut away drawing of hammer swage.