Forum

Market

- Nydelig publisert Webley No. 5 Army Express

- Engelsk pattern 1751 infanteri sabel

- Engelsk spadroon

- Winchester High Wall 38-55

- Smith & Wesson model 2.

- Kjøper Engelske millitære flintlåsvåpen

- " Hevarm " til Kongsberg kammerlader

On this day

26 October 1811

The Danish-Norwegian frigate Najaden was launched. Najaden was built in 1811 and equipped with 36 cannons. Later it was upgraded to 42 cannons. The frigate's career was short-lived: It was sunk during the Battle of Lyngør on 6 July 1812 by the... Read more ...

The frigate Najaden was set afloat

The Danish-Norwegian frigate Najaden was launched. Najaden was built in 1811 and equipped with 36 cannons. Later it was upgraded to 42 cannons. The frigate's career was short-lived: It was sunk during the Battle of Lyngør on 6 July 1812 by the British ship of the line HMS Dictator . Najaden was then under the command of Captain Hans Peter Holm.

Chat

Offline

No chatting right now.

(You must be logged in to the forum to chat.)

Featured article

The Norwegian government started selling the 12 mm Remington rolling block rifles out of service early in the 1900s. This is the story about their civilian use.

The Norwegian Remington rolling block in the 1900s

Muzzleloader and Patched Roundball

About

AboutPublished: 24 November 2007 by Øyvind Flatnes.

Edited: 24 November 2007.

Views: 28000

Les artikkel på norsk

Les artikkel på norsk

The patched roundball is said to be an early American invention, if it's right I don't know. It was used in the American woods from around 1740, probably a little earlier. The principle behind the patched roundball is simple: By wrapping the undersized roundball in a piece of greased cloth and then forcing it down the barrel the problem of loading a rifle without hammering the bullet down the bore was solved. The patch was as mentioned greased, often with bear fat. The fat helped keeping the fouling soft, which also made the loading easier. The most common patching material was linen or cotton which had to be tightly woven to survive the travel up and down the bore. Some will claim that leather (buckskin) was used as patching, but I doubt that was very common. Leather was too costly for a hunter or farmer to be shot out of a rifle.

Find out more!

You can learn more about the history and practical use of muzzle-loading rifles and patched roundballs in the brand new book From Musket to Metallic Cartridge: A Practical History of Black Powder Firearms.

Loading a Rifled Muzzleloader with Roundball

The things you need are:

- A muzzleloading rifle with flint or percussion ignition.

- Black powder and caps (or flints if it's a flintlock.)

- Some roundballs.

- Linen or cotton patches. Denim is good too.

- Bullet lube. Some people use saliva.

- A bullet starter.

The Patch

Keep in mind that it has to be durable enough to resist the strain it is to be shot out of a bore. When you examine a patch you have found after a shot it should not be burned or torn. If they are burned or torn and you experience lousy accuracy, well, then the problem is most likely found.The thickness of the patch is determined by the relationship between the groove diameter of the rifle and the roundball you are using. Let's say you are using a .50 cal. rifle who's groove diameter is .509". The bullet you are using has a diameter of .495". By calculating it as follows you can get an idea of how thick the patching should be: Groove diameter: .531" minus ball diameter : .495" = .036" i difference. Now we can divide .036" in two and minimum thickness will be .018". (There will be cloth on both sides of the bullet, that's why we divide it by two). The thickness of the patches and the bullet diameter can be measured with a micrometer.

The process of loading

1. Make sure that the barrel is dry, run a few dry patches up and down the bore. (Never run a dry patch down a bore with fouling in it or it will get badly stuck down there.) Snap off a few caps if it is a percussion gun. This dries/burns up any remaining oil in the nipple.

2. Measure or weigh up a suitable charge and pour it down the barrel. A rule of thumb is 50 grains for .50 cal. rifle, 45 grains for a .45 cal. and so on. Keep your face away from the muzzle in case the charge ignites.

3. Place a greased patch over the muzzle.

4. Place a roundball on the patch and center it. Push it down with the thumb until it is flush with the muzzle, or as far as you get it. Tight fitting combinations can be hard to push with the thumb.

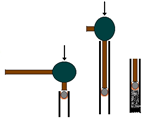

5. Take your starter and place it on the ball as shown below. Give it a quick thump.

6. Do the same thing with the long rod on the starter. See illustration below.

7. Take your ramrod and gently push the ball down the bore until it is seated against the powder. There should be no air gap between the ball and powder. That could make the barrel blow up. See below. Again, remember to keep your face away from the muzzle, the gun is now loaded. Also remember to keep the muzzle in a safe direction at all times!

8. Remove the ramrod from the barrel.

9. Cap the rifle if it is a percussion or prime it with priming powder if it is a flintlock.

10. Cock the hammer and fire!